Lack of power while accelerating.

- Sgt-Mike-Larry

- Member

- Posts: 13

- Joined: Wed Mar 07, 2012 5:46 am

Lack of power while accelerating.

Hi guys,

I have just recently adjusted my valves, timing & points according to the Volkswagen workshop manual.

I was having some point’s issues last week and spent all Sunday doing jobs I had been meaning to do for a while, all went well everything seemed to work for me. Fired up the engine and it sounded different sounded meaner like it was ready to take on the road, but to my disappointment it lost its beetle whistle as I drove away I love driving past other cars and hear the Beetles whistle as it scoots past with a smile. As I drove it to work yesterday The car sounded like it was revving like it should but it wasn’t picking up speed like it used to it still makes it to 100 Kms an hour but takes its time and it tackles hills crawl down to about 60 kms per hour depending on the incline, I guess my question to you guys would be what have I done incorrectly to lose the power when I put my foot down. Seeing as when I was going through my valves half of them were way out of adjustment when I did them, so I thought that it would run great!

Any help or pointers would be great as I would love to get it sorted.

Kindest regards,

Mike.

I have just recently adjusted my valves, timing & points according to the Volkswagen workshop manual.

I was having some point’s issues last week and spent all Sunday doing jobs I had been meaning to do for a while, all went well everything seemed to work for me. Fired up the engine and it sounded different sounded meaner like it was ready to take on the road, but to my disappointment it lost its beetle whistle as I drove away I love driving past other cars and hear the Beetles whistle as it scoots past with a smile. As I drove it to work yesterday The car sounded like it was revving like it should but it wasn’t picking up speed like it used to it still makes it to 100 Kms an hour but takes its time and it tackles hills crawl down to about 60 kms per hour depending on the incline, I guess my question to you guys would be what have I done incorrectly to lose the power when I put my foot down. Seeing as when I was going through my valves half of them were way out of adjustment when I did them, so I thought that it would run great!

Any help or pointers would be great as I would love to get it sorted.

Kindest regards,

Mike.

-

fatalifeaten

- Senior Member

- Posts: 512

- Joined: Sun Feb 03, 2008 12:05 am

- Location: The 480

...half were out? how far? What did you adjust them to, and are you sure you adjusted them correctly / in proper order? "sounding meaner" to me means your valve train is a lot more chatty, which immediately makes me think those valves are too loose or adjusted in the wrong sequence.

That's just my feel on it after reading your post, I could be hitting the wrong crackpipe today too...

That's just my feel on it after reading your post, I could be hitting the wrong crackpipe today too...

- Sgt-Mike-Larry

- Member

- Posts: 13

- Joined: Wed Mar 07, 2012 5:46 am

Hi Fatal,

This is what I did not sure if have done somthing wrong here but this is the path I took,

No.1 - 2 -3 -4. and to make sure I was adjusting correct valves to which cylinder I watched which direction the Rotor arm was pointing to following its spark lead through to cylinder and working on that cylinders valves, once I was happy with the adjustment I rotated the pully around. to next cylinder.

I used the (0.15 mm) feeler gauge for gaps.

On the plus side... the horrible leak that was coming from my main engine seal has completely stopped! so something worked well!

I also noticed tonight when I got home the engine was quite HOT using the poor mans tech holding the dip stick almost burning my fingers, which never happens the engines dip stick is always safe to hold, it also seemed to backfire when cold now, so I have definately botched somthing up!

From Fatals coment I believe that I have incorrectly adjusted these as you said wrong order... Im scratching my head but the only thing I can think of that I have done wrong was possibly turn the pully clock wise instead of counter clockwise.... which would make sence.

If this is the case, how do I go about fixing this horrible mess I have created for myself!? was I at least on the right track in what I was doing?

If I continue to drive with this what am I likely to do to the engine? As I live 60 minutes away from where I do all the work on my vehicle! which is a bit of a hassle but I love driving it!

This is what I did not sure if have done somthing wrong here but this is the path I took,

No.1 - 2 -3 -4. and to make sure I was adjusting correct valves to which cylinder I watched which direction the Rotor arm was pointing to following its spark lead through to cylinder and working on that cylinders valves, once I was happy with the adjustment I rotated the pully around. to next cylinder.

I used the (0.15 mm) feeler gauge for gaps.

On the plus side... the horrible leak that was coming from my main engine seal has completely stopped! so something worked well!

I also noticed tonight when I got home the engine was quite HOT using the poor mans tech holding the dip stick almost burning my fingers, which never happens the engines dip stick is always safe to hold, it also seemed to backfire when cold now, so I have definately botched somthing up!

From Fatals coment I believe that I have incorrectly adjusted these as you said wrong order... Im scratching my head but the only thing I can think of that I have done wrong was possibly turn the pully clock wise instead of counter clockwise.... which would make sence.

If this is the case, how do I go about fixing this horrible mess I have created for myself!? was I at least on the right track in what I was doing?

If I continue to drive with this what am I likely to do to the engine? As I live 60 minutes away from where I do all the work on my vehicle! which is a bit of a hassle but I love driving it!

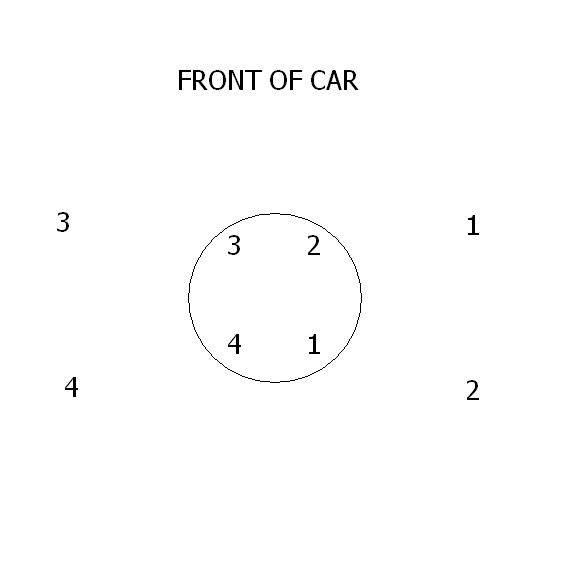

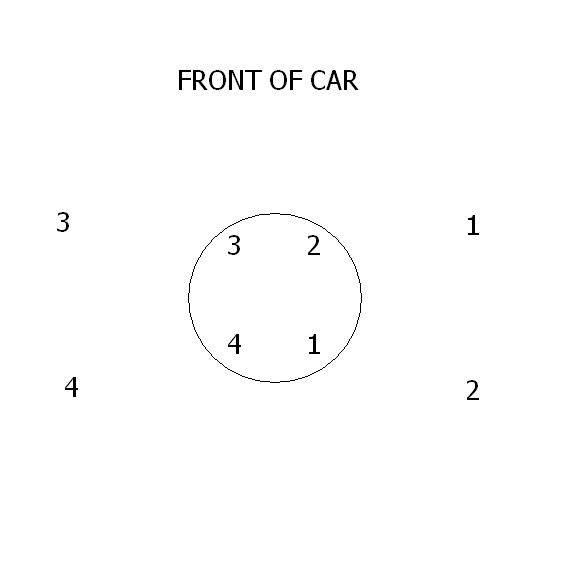

- Attachments

-

- cylinder order.jpg (13.15 KiB) Viewed 12650 times

- Sgt-Mike-Larry

- Member

- Posts: 13

- Joined: Wed Mar 07, 2012 5:46 am

After Further inspection of A.) the car and B.) the Volkswagen rule book....

fatalifeaten you would be 100% Correct! I have incorrectly adjusted the valves in the wrong sequence, will be picking up new rocker cover gaskets tomorrow to fix my stupidity. Thank you for your assistance! I really appreciate it Next time read twice adjust once!!!

Next time read twice adjust once!!!

fatalifeaten you would be 100% Correct! I have incorrectly adjusted the valves in the wrong sequence, will be picking up new rocker cover gaskets tomorrow to fix my stupidity. Thank you for your assistance! I really appreciate it

-

fatalifeaten

- Senior Member

- Posts: 512

- Joined: Sun Feb 03, 2008 12:05 am

- Location: The 480

.015? Yoikes! Waaaaaaay too loose. .006 intakes and exhausts. That's part of why they're so chatty, and definitely part of your power loss as well.

Also, your diagram has cylinder positions swapped. 1 and 2 are passenger side of the car, 3 and 4 driver side. If you have factory cylinder head tins, they're also marked on the tin outskirts to help you remember.

Here's a diagram to help. Numbers on the outside are the cylinder positions on the engine, the circle in the center is where the corresponding wire should be connected to your distributor cap.

Here's a caveat. If the last person to work on your engine got the distributor drive gear in 180 degrees out, this won't work. In that case, your #1 position would be at the (roughly) 11 O'clock position instead of the 5 o"clock position as noted in that diagram. If so, adjust accordingly. being 180 out won't kill you, but from experience, it runs just a little "off", if that makes sense

Here's what I do.

* Never adjust the valves unless the car is completely cold. If you've driven it today, adjust them before you start it up tomorrow. Otherwise your measurements can be off (and if it's too hot your hands will hate you)

* Get car to TDC (Note: If you have a degreed pulley this is really simple, if not, make sure the TDC notch is lined up while pointed at #1 and you're good). Pop the Distributor cap and make sure you're lined up on #1 at TDC

* Adjust intake and exhaust valves on #1 to .006

* Crank pulley COUNTERCLOCKWISE 180 degrees. This should line you up on #2. Adjust those valves.

*CLOCKWISE 180 degrees again to #3. I like to use a big crescent wrench to turn the pulley with. Flat, easy to get in there, and plenty of leverage Adjust the #3 valves.

*Clockwise again to #4. Adjust those valves.

* Button up. Use new valve cover gaskets. Hopefully you're getting good cork ones and not the cruddy rubber ones, those stink.

Fire it up and enjoy. Repeat every 3000 miles or 3 mos if you don't go 3k miles in that time period. I usually do my oil change, valve adjustments, zerk greasing, point adjustment check, belt check, etc... All in a morning every 3k miles. That way they're all on schedule. Takes maybe an hour once you get a routine down.

Also, your diagram has cylinder positions swapped. 1 and 2 are passenger side of the car, 3 and 4 driver side. If you have factory cylinder head tins, they're also marked on the tin outskirts to help you remember.

Here's a diagram to help. Numbers on the outside are the cylinder positions on the engine, the circle in the center is where the corresponding wire should be connected to your distributor cap.

Here's a caveat. If the last person to work on your engine got the distributor drive gear in 180 degrees out, this won't work. In that case, your #1 position would be at the (roughly) 11 O'clock position instead of the 5 o"clock position as noted in that diagram. If so, adjust accordingly. being 180 out won't kill you, but from experience, it runs just a little "off", if that makes sense

Here's what I do.

* Never adjust the valves unless the car is completely cold. If you've driven it today, adjust them before you start it up tomorrow. Otherwise your measurements can be off (and if it's too hot your hands will hate you)

* Get car to TDC (Note: If you have a degreed pulley this is really simple, if not, make sure the TDC notch is lined up while pointed at #1 and you're good). Pop the Distributor cap and make sure you're lined up on #1 at TDC

* Adjust intake and exhaust valves on #1 to .006

* Crank pulley COUNTERCLOCKWISE 180 degrees. This should line you up on #2. Adjust those valves.

*CLOCKWISE 180 degrees again to #3. I like to use a big crescent wrench to turn the pulley with. Flat, easy to get in there, and plenty of leverage Adjust the #3 valves.

*Clockwise again to #4. Adjust those valves.

* Button up. Use new valve cover gaskets. Hopefully you're getting good cork ones and not the cruddy rubber ones, those stink.

Fire it up and enjoy. Repeat every 3000 miles or 3 mos if you don't go 3k miles in that time period. I usually do my oil change, valve adjustments, zerk greasing, point adjustment check, belt check, etc... All in a morning every 3k miles. That way they're all on schedule. Takes maybe an hour once you get a routine down.

-

Blue Baron

- Senior Member

- Posts: 879

- Joined: Sun Jan 18, 2009 8:34 pm

- Location: Tampa, Florida

- Sgt-Mike-Larry

- Member

- Posts: 13

- Joined: Wed Mar 07, 2012 5:46 am

Thank you Fatal for the operation procedure!

That is brilliant! Thank you so much.

Will be getting under the battle wagon tonight to fix these up, haven’t driven it for 2 days so it will be lovely and cold... plus I probably would have knackered up my valves if I had kept on driving it!

Thanks again!

Kindest regards,

Mike.

That is brilliant! Thank you so much.

Will be getting under the battle wagon tonight to fix these up, haven’t driven it for 2 days so it will be lovely and cold... plus I probably would have knackered up my valves if I had kept on driving it!

Thanks again!

Kindest regards,

Mike.

-

fatalifeaten

- Senior Member

- Posts: 512

- Joined: Sun Feb 03, 2008 12:05 am

- Location: The 480

-

fatalifeaten

- Senior Member

- Posts: 512

- Joined: Sun Feb 03, 2008 12:05 am

- Location: The 480